SAP One-step and two-steps stock transfer posting procedures

In the previous post about stock transfer between plants in general, I have explained that it can be done with Stock Transfer Posting (which solely in SAP MM Inventory Management component) or Stock Transport Order (which also involves SAP MM Purchasing and SAP SD components).

In this post, I will explain Stock Transfer Posting in more details.

Unlike stock transfer posting from one storage location to another storage location which can be carried out for all stock types, plant to plant stock transfer posting can only be carried out from unrestricted-stock to unrestricted-stock in both plants.

In term of how to do the transaction, stock transfer posting can be done in one-stop procedure or two-steps procedure.

STOCK TRANSFER POSTING IN ONE-STEP PROCEDURE

The advantage of one-step stock transfer posting is the simplicity that we only have to do a single transaction for it.

In that single transaction, the unrestricted-stock in issuing plant is reduced and the unrestricted-stock in receiving plant is increased. The unrestricted-stock quantity in one storage location of a plant can be seen in MARD table – LABST field.

The movement type used in this transaction is 301 (and 302 to cancel it). After posting the stock transfer transaction, SAP will create a material document. For every item we enter in the transaction, SAP will create two material document items:

– one item for reducing the unrestricted-stock in issuing plant

– one item for increasing the unrestricted-stock in receiving plant.

– one item for reducing the unrestricted-stock in issuing plant

– one item for increasing the unrestricted-stock in receiving plant.

The transaction can be done with MIGO or MIGO_TR, and MB1B tcodes.

The user that performs the one-step stock transfer posting must have authorization to do the goods movement transaction in both plants.

The authorization objects required for this transaction:

- M_MSEG_BWA – Goods Movements: Movement Type

- Activity: 01, 02, 03

- Movement type: 301-302

- M_MSEG_WWA – Goods Movements: Plant

- Activity: 01, 02, 03

- Plant: issuing plant, receiving plant

- M_MSEG_LGO – Goods Movements: Storage Location

This authorization object is needed if only you activated "Authorization Check for Storage Locations" on the configuration. To check whether it's activated or not, go to following SPRO tcode menu path: Materials Management – Inventory Management and Physical Inventory – Authorization Management – Authorization Check for Storage Locations.- Activity: 01, 02, 03

- Movement type: 301-302

- Plant: issuing plant, receiving plant

- Storage location: issuing sloc, receiving sloc

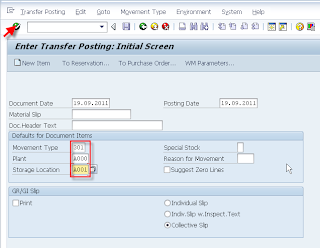

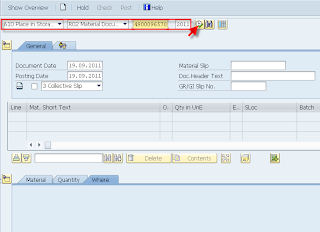

On the following image you can see the screenshot of MIGO / MIGO_TR tcode to do the stock transfer posting from a plant to another plant in one-step procedure. The red boxes indicate the fields that need to be filled/chosen.

The above image is © SAP AG 2011. All rights reserved

Click "Check" button to check your input. If there is no error message, click "Post" button.

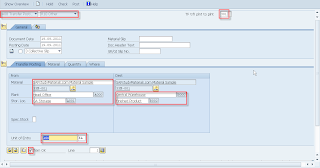

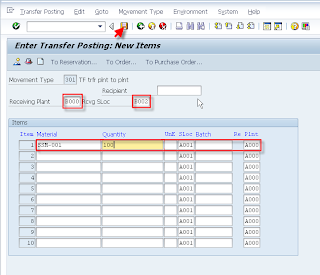

On the following images you can see the screenshot of MB1B tcode to do the stock transfer posting from a plant to another plant in one-step procedure. The red boxes indicate the fields that need to be filled/chosen.

The above image is © SAP AG 2011. All rights reserved

The above image is © SAP AG 2011. All rights reserved

We can plan one-step stock transfer posting with stock transfer reservation (MB21 tcode).

STOCK TRANSFER POSTING IN TWO-STEPS PROCEDURE

In two-steps stock transfer posting procedure, we have to do two transactions in order to reduce the stock in issuing plant and increase the stock in receiving plant.

The first one is "Remove from storage" transaction, that will decrease the unrestricted-stock in the issuing plant (MARD table – LABST field) and increase the "stock in transfer (plant)" (MARC table – UMLMC field) in the receiving plant.

The transaction can be done with MIGO, MIGO_TR, or MB1B tcodes. The movement type for the transaction is 303 (and 304 to cancel it).

After posting the "Remove from storage" transaction, SAP will create a material document. For every item we enter in the transaction, SAP will create two material document items:

– one item for reducing the unrestricted-stock in issuing plant

– one item for increasing the stock in transfer (plant) in receiving plant.

After posting the "Remove from storage" transaction, SAP will create a material document. For every item we enter in the transaction, SAP will create two material document items:

– one item for reducing the unrestricted-stock in issuing plant

– one item for increasing the stock in transfer (plant) in receiving plant.

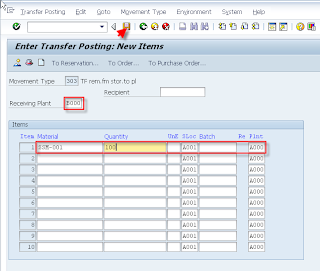

On the following image you can see the screenshot of MIGO / MIGO_TR tcode to do the "Remove from storage" transaction. The red boxes indicate the fields that need to be filled/chosen.

The above image is © SAP AG 2011. All rights reserved

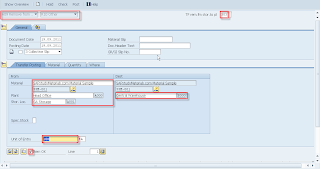

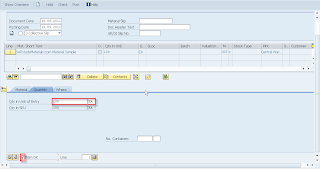

On the following images you can see the screenshot of MB1B tcode to do the "Remove from storage" transaction. The red boxes indicate the fields that need to be filled/chosen.

The above image is © SAP AG 2011. All rights reserved

The above image is © SAP AG 2011. All rights reserved

The second transaction is "Place in Storage" transaction that will decrease the stock in transfer (MARC table – UMLMC field) and increase the unrestricted-stock in the receiving plant (MARD table – LABST field).

The transaction can be done with MIGO/MIGO_TR or MB1B tcodes. The movement type for the transaction is 305 (and 306 to cancel it).

Although you can post the "place in storage" transaction without any reference documents (as long as there as sufficient "stock in transfer" in the receiving plant) with MIGO/MIGO_TR/MB1B tcodes, it's better to post it by referring to the material document posted from the related Remove from storage transaction with MIGO/MIGO_TR tcodes. By doing so, you don't have to re-enter the item details of the transaction, just the reference material document number then SAP will copy the data from the reference document. You can edit the data before posting the "place in storage" transaction, i.e the quantity data in case of partially receipt.

After posting the "Place in storage" transaction, SAP will create a material document. For every item we enter in the transaction, SAP will create only one material document item:

– one item for reducing the stock in transfer (plant) and increasing the unrestricted-stock in the receiving plant.

– one item for reducing the stock in transfer (plant) and increasing the unrestricted-stock in the receiving plant.

On the following image you can see the screenshot of MIGO / MIGO_TR tcode to do the "Place in storage" transaction that refers to a "remove from storage" material document. The red boxes indicate the fields that need to be filled/chosen.

The above image is © SAP AG 2011. All rights reserved

The above image is © SAP AG 2011. All rights reserved

Click "Check" button to check your input. If there is no error message, click "Post" button.

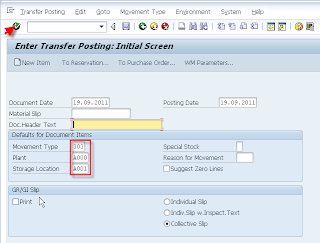

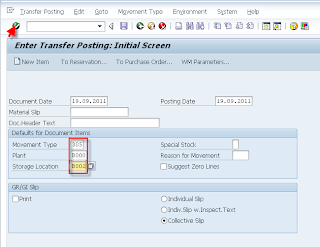

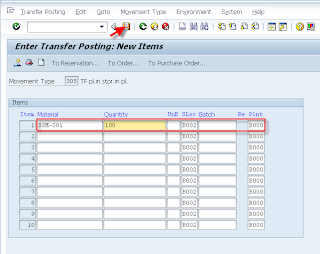

On the following images you can see the screenshot of MB1B tcode to do the "Place in storage" transaction (we can't refer to "remove from storage" material document in order to post the "place in storage" transaction with MB1B tcode). The red boxes indicate the fields that need to be filled/chosen.

The above image is © SAP AG 2011. All rights reserved

The above image is © SAP AG 2011. All rights reserved

Why should we do two transactions if we can do it with only one transaction? Although it seems more complicated, actually by doing two transactions we can:

- Monitor the stock in transfer between plants. It's better to do this in two transactions if there are difference between plants in terms of place (location) and time when the issuing and receiving process occur.

- Separate the authorization between the one who removes from storage (issues) the stock in issuing plant, and the one who places in storage (receives) the stock in receiving plant. So, we can set that the one who issues the stock in issuing plant can't receive the stock in receiving plant, and vice versa.The authorization objects required for these transactions:

- M_MSEG_BWA – Goods Movements: Movement Type

- Activity: 01, 02, 03

- Movement type: 303-304 (for Remove From Storage transaction) or 305-306 (for Place In Storage transaction)

- M_MSEG_WWA – Goods Movements: Plant

- Activity: 01, 02, 03

- Plant: issuing plant (for Remove From Storage transaction) or receiving plant (for Place In Storage transaction)

- M_MSEG_LGO – Goods Movements: Storage Location

This authorization object is needed if only you activated "Authorization Check for Storage Locations" on the configuration. To check whether it's activated or not, go to following SPRO tcode menu path: Materials Management – Inventory Management and Physical Inventory – Authorization Management – Authorization Check for Storage Locations.- Activity: 01, 02, 03

- Movement type: 303-304 (for Remove From Storage transaction) or 305-306 (for Place In Storage transaction)

- Plant: issuing plant (for Remove From Storage transaction) or receiving plant (for Place In Storage transaction)

- Storage location: issuing sloc (for Remove From Storage transaction) or receiving sloc (for Place In Storage transaction)

- M_MSEG_BWA – Goods Movements: Movement Type

To carry out a stock transfer from plant to plant for a material that is subject to split valuation at the receiving point, we have to use the one-step procedure or a stock transport order.

In the next article, I will explain about stock transfer posting between plants in term of organization level (within a company code and cross-company codes). Stay visiting this blog.

Reblogged from iERP.us

what will be the nature of those transaction.

ResponderBorrar